DELALLE FAMILY - 4 GENERATION OF ARTISTS

DELALLE FAMILY - 4 GENERATION OF ARTISTS

DELALLE FAMILY - 4 GENERATION OF ARTISTS

DELALLE FAMILY - 4 GENERATION OF ARTISTS

TAPISTRY

The bigest tapistry in the world, made by Frane Delalle, entered in Guiness

book of records with the surface of 1242 m2.

Inside the military fascility in Iraq, the large semi circular wall in the entrance

hall was the

place where the tapistry named "History of Iraq" was placed in

1988.

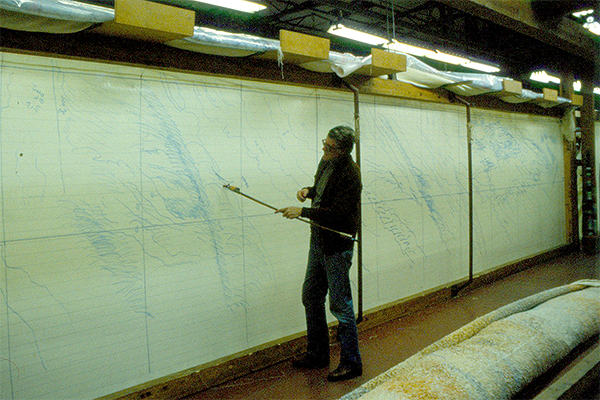

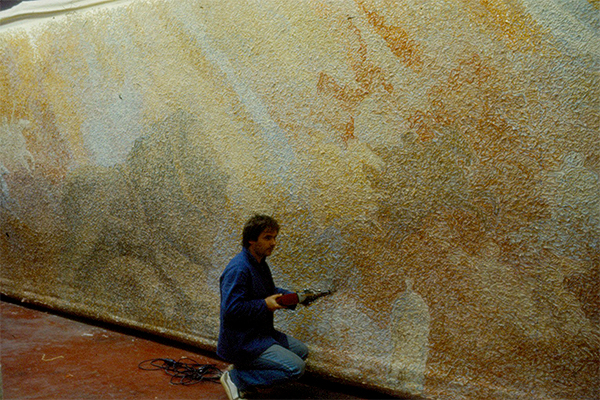

This hand-made work was produced in factory in Zabok, nowdays Croatia, in sections, and

mounted on

the

spot.

Height of sections is from 8 to 11 meters, and the whole composition is aprox. 120 meters

long.

The destiny of this tapistry, after the wars in Iraq, is unknown.

Taking photos

inside

the

facility

was not allowed at that time. Only the fotos taken outside the factory before transport, are preserved.

Unfortunately, a few sections - on extreme left and right side - are missing.

The process of manufacturing this extremely large and tall tapistry, was

a chalange, for both artist and factory workers.

More than 30 people were involved in production - operators on needle

punching machines, people in charge of preparing looms, trimming and cleaning woll.

During six months, under the supervision of an artist, the work was finished and ready to transport to Iraq.

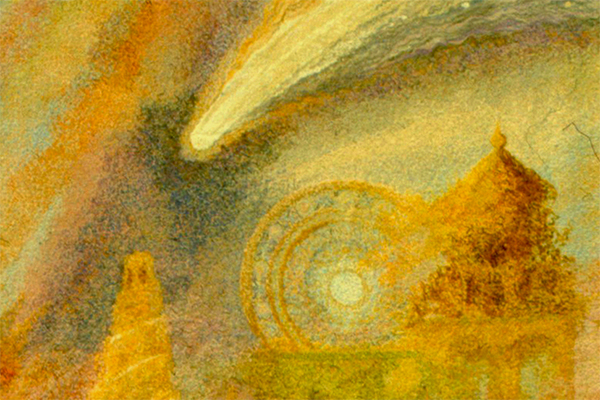

His first tapistry , made in 1975. for the congress hall in hotel

Croatia in Cavtat. Size 18 x 4m.

Central motif is the old town of Dubrovnik, surrounded

by the fleet

of

mechant ships, that broth welth to this dalmatian city.

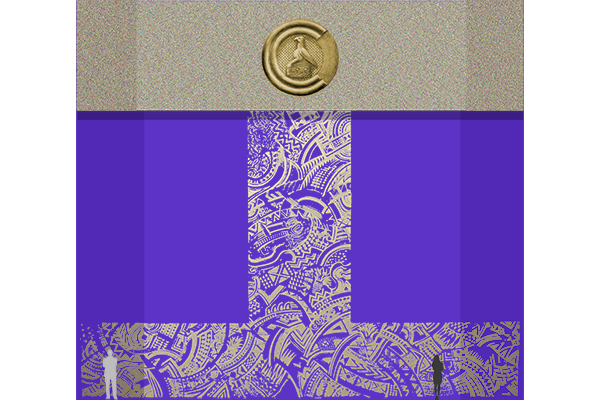

The stage curtain - size 16 x 11 m. Golden leaves on

textile.

State coat of arms - diameter 4.5 m. Brass, hand made. Original border (CC for

Congress Center) was replaced with the point star.

The former SHERATON Hotel, today Rainbow Towers Hotel, was built in 1982 / 1986.